Laser Shaft Alignment |

21 December, 2024 - Saturday

|

Shaft alignment is the correction of the relative position of two machines that are connected, such as a motor and a pump, so that the center lones to the shaft form a straight line when the machines are working at normal operating temperature. Shaft alignment means moving the front and rear pair of feet of one machine, verically and horizontally, until the shafts are aligned.

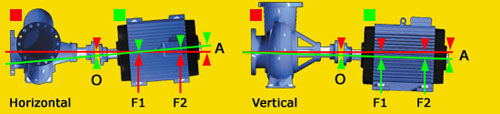

There are two components of misalignment: angular and offset. There are also two planes of potential misalignment: the horizontal plane (side to side) and the vertical plane (up and down).Each alignment plane has offset anf angular components, so there are four alignment parameters to be measured and corrected.

The benefits of accurate shaft alignment are:

- reduced vibration and noise,

- redused energy consumption of the machine,

- increased bearing life,

- reduced stress on couplings,

- reduced wear on seal,

- increased machinery uptime, efficiency and productivity.

Alignment systems using laser technology offer an easy, quick a highly accurate method to measuring and adjusting misalignments.

For alignment purposes we use Fixturlaser® Shaft 100, which makes the most accurate coupling alignment possible.

What types of defects can be determined?

- misalignment of paralel couplings,

- angular misalignment,

- combination of offset and angular misalignment,

- misalignment of horizontal machines,

- misalignment of vertical machines,

- the effect of thermal growth – "Thermal offset",

- soft foot - "Soft check",

- misalignment of more units connected to each other with rotating shafts - "Machine train".

Combination of angular and offset misalignment in case of a horizontal machine:

Illustration of damaging forces as a result of misalignment:

Back to Services

|